Why choose Tungsten Carbide Tips?

Tungsten Carbide Tips form an extremely dense crystal structure called hexagonal crystal. It is one of the best tips that you can buy for industrial use.

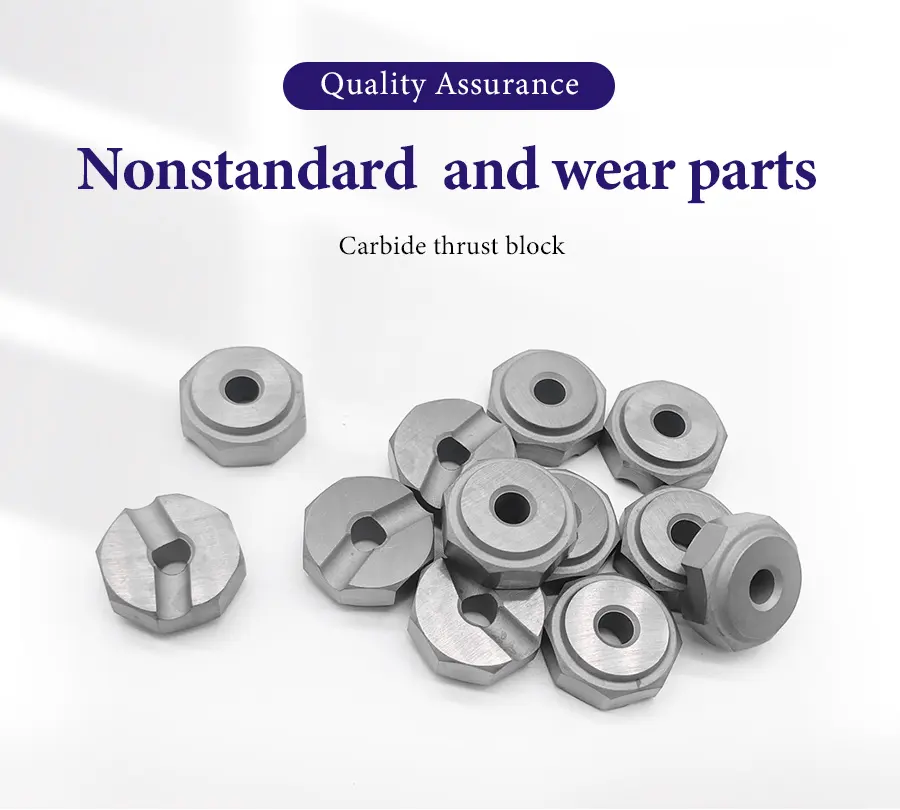

Features of Tungsten Carbide Tips:

1. High hardness

2. High strength at high temperature

Since Tungsten Carbide Tips has high strength at high temperature and low, warm extension coefficient, it is an ideal unrefined substance for slicing instruments to be utilized in a high-temperature and fast climate.

High protection from erosion

Tungsten carbide is an amazingly steady substance, and it doesn’t oxidize at typical temperatures in air. Also, it isn’t frame a strong arrangement with different components and keeps stable qualities even in serious conditions.

We produce both norm and client necessities items. We can give proficient plans to tweaked tungsten carbide items.

We do all the cycles from the start in our production line, from blend grade powder to brazing, accuracy granulating. So we can handle the quality right to results.

We’re sure to offer you superior grade, sensible value items.

Zhuzhou Kerui Cemented Carbide mainly specializes in manufacturing tungsten Carbide Tips, Carbide Tips tools, CNC insert, mechanical parts, mining tools, nonstandard tungsten carbide tools, thermal spray powder, grade powder, and other tungsten carbide products.

Visit our sites today!

Website: https://www.keruicementedcarbide.com/

See similar content: –

What are the Factors of Tungsten Carbide Rod?